Spooling of Tungsten Wire

As a high performance material, Tungsten has high melting point (3410˚C), high corrosion resistance, high density, low vapor pressure, low thermal expansion combined with good thermal conductivity, sufficient electrical resistance, high modulus of elasticity. It is mainly applied for lamps, vacuum metalizing, aluminizing kinescope, plastics, mirrors and heater elements for decoration articles.

Surface finish is supplied:

· Black, as drawn condition, where drawing lubricants and oxides are retained on the surface,

· Cleaned condition by firing in hydrogen or electrochemical etching.

· Aquadag layer on the surface of wire should be removed before using the wire is not suitable for contacting with iron, nickel, carbon, when the temperature is higher than 1000. The wires should be preserved in dry room, in which the relative humidity should not surpass 65%, and keeping away from acid or alkali atmosphere.

· Cleaned wires should be preserved in dry vessels.

Spooling

Tungsten wire is spooled on clean, defect free spools. For very large diameters, tungsten wire is self coiled. Spools are level filled without piling near flanges. The outer end of the wire is properly marked and attached securely to the spool or self coil.

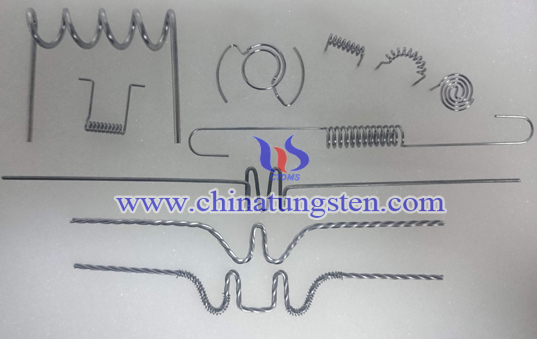

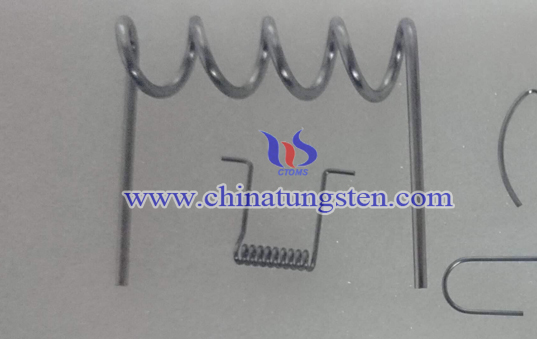

Regular Stran

Regu larstranded wire is available in ready to use coils, straight pieces of wire cut to specific lengths and wire in random lengths.

Open stranded wire holds more evaporation because of better capillary action and reduces balling up evaporation. This contributes to longer coil life.

Core stranded wire improves wetting qualities for the most metalizing applications. This construction is designed to pre-wet the entire coil to achieve effective wetting on the first operation.